Introducing greenhouse equipment - heating equipment of greenhouses

In this article, we will try to introduce the equipment used and useful in the greenhouse in 12 parts and review the important points in their preparation and use. In this section, we will introduce greenhouse heating equipment.

To heat greenhouses other than sun, which is a natural heat source, materials such as oil, coal, wood, oils, natural gas and electricity, etc. are used. In order to provide uniform heat and temperature control on cold winter nights, these energy sources must be equipped with automatic devices. The thermal system of greenhouses depends on the type of greenhouse and the availability of cheap fuel. Institutions with large and numerous greenhouses use central thermal devices (hot water radiators) or steam heating systems, these two methods cost a lot of basic, but can be justifiable because of cheap fuel.

Types of heating systems

Greenhouse heating systems can be divided into three categories:

Heating air by furnace

Hot Water Systems

Underground Heating Systems

A) Hot air furnaces:

This system is composed of a cubic or cylindrical furnace located in the middle of the torch. The flame of the combustion of the fuel heats the furnace, the air around the furnace is heated, then the hot air passes through the spiral tubes of the heat converter, the air passes through these pipes gives its heat to the greenhouse and when it comes out of the chimney there is a small heat, it should be noted that the furnaces and heaters must be connected to the chimney because the gases emitted from the fuel fuel They are toxic to plants.

B) Fan heater:

In this heating system, the cold air of greenhouses is sucked by a fan and dragged onto the furnace and the network of heat pipes, so the air is heated and emitted from the window above the heater as a continuous airflow inside the greenhouse, the hot air rises due to lightness, but with the loss of heat it goes down again, which leads to the establishment of an airflow. The furnaces have two thermostats, one to turn off and on the torch and the other to control the blower. The work of this blower thermostat is to prevent the blower from turning on before the temperature of the furnace reaches its maximum, and also by turning off the torch, as long as the air is still hot, it does not allow the fan to shut down.

c) Hot water systems:

This system is composed of a hot water boiler, a water pump for filling the reservoir of water purification equipment, control panel and piping network.

Hot water boilers are made of steel, which are completely sealed by welding their seams. These crows are usually type 2 or 3 tubes, meaning that hot air is watered 2 or 3 times in the tank to give its heat to the water. The hot water system of most greenhouses is under pressure. By increasing the water temperature in this system and installing a pump in the heat circuit, the source is rapidly transferred to the greenhouse air.

To control the system, a thermostat is installed on the boiler that keeps the water temperature constant and mixing valves are located on several branches of the outlet of the boiler that adjust the temperature of each heater pipe.

In some treasuries, this system is also equipped with a computer that automatically uses heating and ventilation devices by receiving heat information from inside and outside the greenhouse to keep the temperature inside constant.

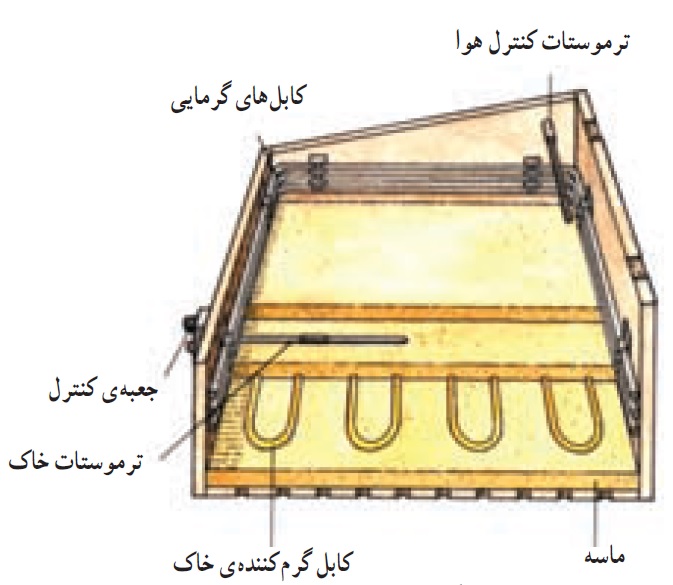

d) Underground heating systems:

Use of electric water heater: In this method, an electric water heater and hot water pipe network and a control pump and thermostats are used which are embedded under pots or plant beds. The hot water pipes under the substrate deliver the same heat to the plant. Hot water pipes may be located at a depth of about 50 cm or use P.V.C pipes and place on insulating polyester insoles and cover the pipes with sand or sheet metal.

.jpg)

Electric thermal elements: These elements are sold as ready and impervious units relative to water, which are placed under the substrate in spiral form and covered with wet sand. Electricity flow generates heat in the elements and heats the surrounding sand and finally the plant bed. A thermostat is also connected to the system to control the temperature. Most of these elements work with urban electricity, but due to the dangerous electricity of the city, 24V elements are also used today. This system is used because it is less expensive.

Service and maintenance of heating systems

In order to achieve a long life without system problems, regular care of diags and heating facilities is a necessity. Negligence in such a task may result in the failure of devices or systems.

A) Steam boilers:

These dings require one to two services per year and all the caps of the device should be visited, clean the soot and the smokestacks will be milled. The walls of the walls should be checked so that they do not have cracking and rust, refractory bricks are not burned, ignition devices, electric motors and propulsion devices are also serviced, the water of the boiler is empty, the water ducts and the pit valves are opened and the other is washed with clean water. Torch spraying should be checked and cleaned and replaced if necessary. Ignition electrodes are removed and checked to replace the clean electron eye and oil flow line filter.

If the torch is not turned on, pay attention to the following:

Is there fuel in the tank?

Is the fuel milk open?

Can the ignition of the electrodes be heard?

Is the relay disconnected?

B) Heaters:

They need six-month care, the radiator cap should be checked so that they do not have cracking, if there are cracks, they should be welded or replaced. Leakage of pipes is checked and worn parts are replaced.

c) Testing environmental controllers:

Test the sensitivity of all automatic keys, sensors and thermostats if they require service or replacement with the help of experts.

.jpg)